Flexibility

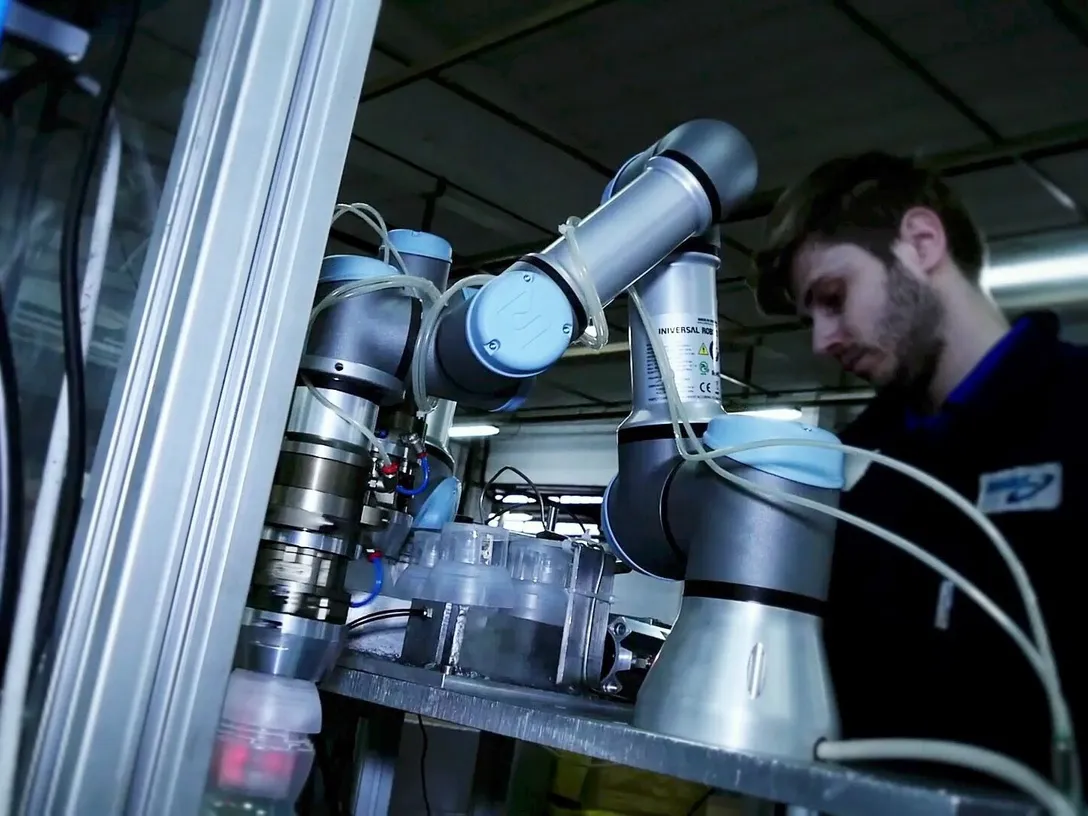

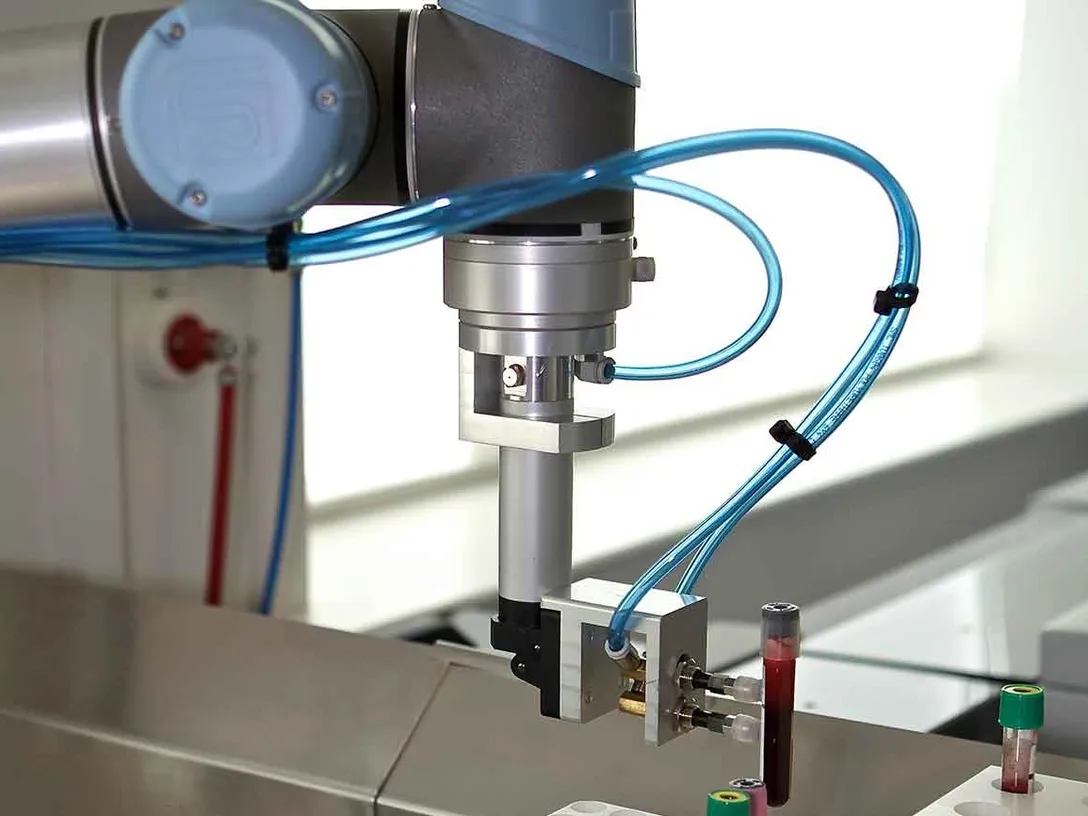

Quickly and easily adapt to new products, even low-volume or quick-turn jobs. Collaborative robot arms can be reprogrammed and redeployed in-house, and can even be mounted on carts for easy mobility.

Productivity

Increase productivity by optimizing utilization of equipment and workers. Cobots can work reliably around the clock without breaks, producing consistently higher-quality products and reducing scrap. And ROI typically occurs in less than a year.

Safety & hygiene

Repetitive tasks are undesirable for human workers, whose attention can slip after hours of the same process. Cobots can reliably perform delicate assembly and consistently load and unload machines for higher quality and reduced scrap.