Training Courses

Course

Course

In this 2-day foundational course, you will learn how to minimize the time required for data analysis by using Minitab. Our experts will teach you how to import data, develop sound statistical approaches to exploring data, create and interpret compelling graphs, and export results.

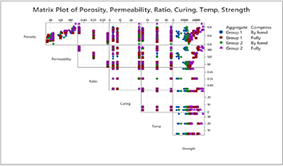

You will practice analyzing a variety of real-world data sets to learn how to align your applications with the right statistical tool, and you’ll interpret statistical output to reveal problems with a process for evidence of an improvement opportunity. Plus, learn the fundamentals of important statistical concepts, such as hypothesis testing and confidence intervals, and how to uncover and describe relationships between variables with statistical modeling tools.

This course places a strong emphasis on making sound decisions based upon the practical application of statistical techniques commonly found in manufacturing, engineering, and research and development endeavors.

Topics Include:

Prerequisites: None

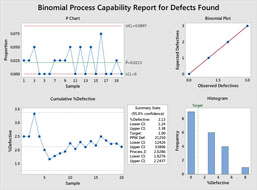

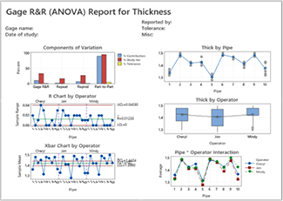

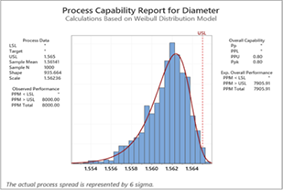

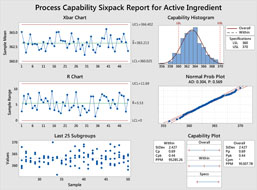

In this course, you will develop the necessary skills to successfully evaluate and certify manufacturing and engineering measurement systems. Our experts will teach you the fundamentals of statistical process control and how these important quality tools can provide the necessary evidence to improve and control manufacturing processes. You will develop the skills to know when and where to use the various types of control charts available in Minitab for your own processes. And you will learn how to utilize important capability analysis tools to evaluate your processes, relative to internal and customer specifications.

The course emphasis is placed on teaching quality tools as they relate to the manufacturing processes.

Topics Include:

Prerequisites: Minitab Essentials

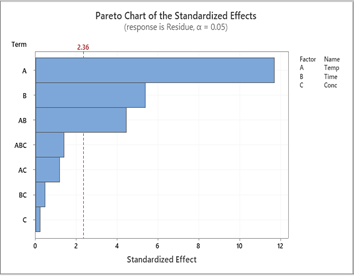

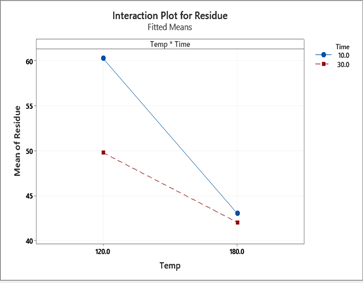

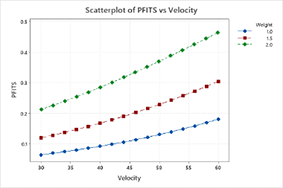

Learn to generate a variety of full and fractional factorial designs using Minitab’s intuitive DOE interface. Real-world applications demonstrate how the concepts of randomization, replication, and blocking form the basis for sound experimentation practices. You will develop the skills necessary to correctly analyze the resulting data to effectively and efficiently reach experimental objectives.

You will use Minitab’s customizable and powerful graphical displays to interpret and communicate experimental results. Then you will learn how to use those results to improve products and processes, find critical factors that impact important response variables, reduce process variation, and expedite research and development projects.

Topics Include:

Prerequisites: Minitab Essentials

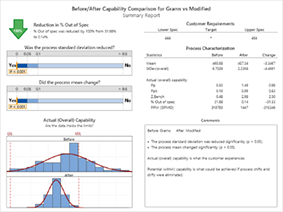

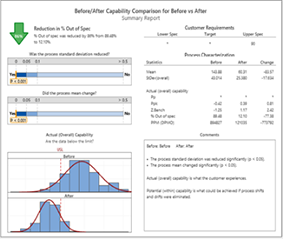

Continue to build on the fundamental concepts taught in the Manufacturing Statistical Quality Analysis course by learning additional tools that can help you improve and control your processes. In this course, you will develop the necessary skills to successfully evaluate and certify manufacturing and engineering measurement systems with multiple gages or different locations on a part. Learn how to evaluate a random sample of product from a lot to determine whether to accept or reject the entire lot. Plus, expand your knowledge of control charting to handle rare events and time-weighted data.

Learn how to utilize important capability analysis tools to evaluate your processes relative to internal and customer specifications. The course emphasis is placed on teaching quality tools as they relate to manufacturing processes.

Topics Include:

Prerequisites: Minitab Essentials, Statistical Quality Analysis

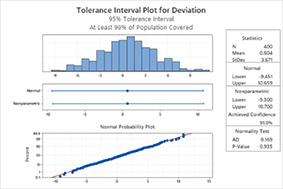

Continue to build on the fundamental concepts taught in the Manufacturing Statistical Quality Analysis course and learn additional tools! You will develop skills to measure quality levels and assess process capability when your data is skewed, has extreme outliers, is multimodal, or is clustered. Expand your knowledge of control charting by learning how to correctly identify special cause variation in the presence of nonnormal data.

You will learn how to successfully use graphical methods and statistical tests to detect nonnormal data and choose an appropriate distribution or transformation for the analysis. Plus, understand the impact of poor measurement resolution and sample size on normality testing.

Topics Include:

Prerequisites: Minitab Essentials, Statistical Quality Analysis

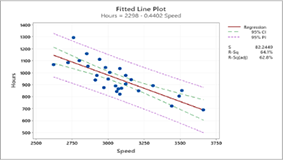

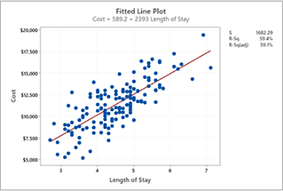

Continue to build on the fundamental statistical analysis concepts taught in the Minitab Essentials course by learning additional statistical modeling tools. The new tools will help you uncover and describe relationships between variables. Hands-on examples illustrate how modeling tools can reveal key inputs and sources of variation in your processes.

Learn how to use statistical models to investigate how processes may behave under varying conditions. This course provides techniques to help you better understand your processes and verify your improvement efforts.

Topics Include:

Prerequisites: Minitab Essentials

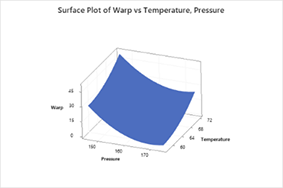

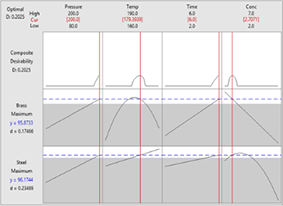

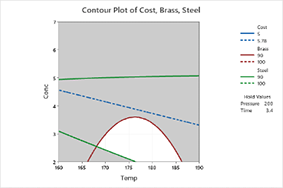

Expand your knowledge of basic 2-level full and fractional factorial designs to those that are ideal for process optimization. You will learn how to use Minitab’s DOE interface to create response surface designs. Plus, you will analyze experimental results using a model that includes quadratics and find optimal factor settings.

Learn how to experiment in the real world by using sequential experimentation, which balances the discovery of critical process information while being sensitive to the resources required to obtain that information. Additionally, learn how to find factor settings that simultaneously optimize multiple responses.

Topics Include:

Prerequisites: Minitab Essentials, Factorial Designs

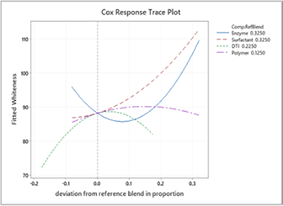

Learn how to handle common DOE scenarios, where modifications to the analysis of classic factorial and response surface designs are necessary due to the nature of the response variable or the data collection process. You will develop techniques for experimental situations often encountered in practice, such as missing data and hard-to-change factors. Plus, build an understanding for how to account for variables (covariates) that may affect the response but cannot be controlled in the experiment.

Explore the opportunities to minimize costs or variability, while simultaneously optimizing an important product or process characteristic. Learn how to find and quantify the effect that factors have on the probability of a critical event, such as a defect, occurring.

Topics Include:

Prerequisites: Minitab Essentials, Factorial Designs

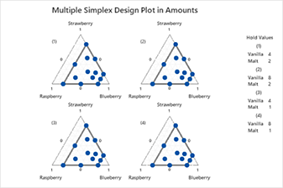

Learn the principles of designing experiments and analyzing the data for processes that involve mixing and blending ingredients, such as those commonly found in the pharmaceutical, chemical, food, and consumer goods industries. By utilizing Minitab’s easy-to-understand interface, you will create experiments designed to study and uncover important process information that is related to mixture processes and has minimal experimental resources. Learn how to interpret graphical and statistical output to understand a mixture’s blending properties and choose the appropriate formulation needed to optimize one or more critical process characteristics.

Topics Include:

Prerequisites: Minitab Essentials, Factorial Designs

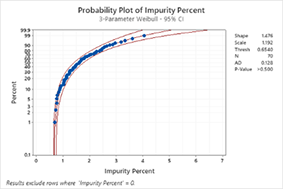

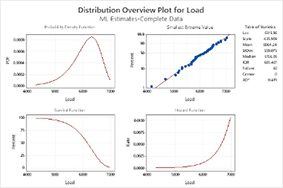

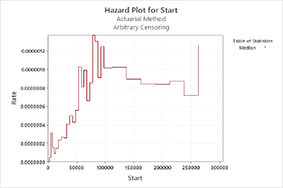

Determine lifetime characteristics of a product using graphical and quantitative analysis methods. Examine case studies containing censored and uncensored data to learn how to correctly handle a wide variety of data structures commonly found in reliability.

Explore the common distributions used to model failure rates and understand their hazard functions so you can develop the necessary skills to choose the appropriate distribution. Model product reliability when product failure comes from different failure types.

Topics Include:

Prerequisites: Minitab Essentials

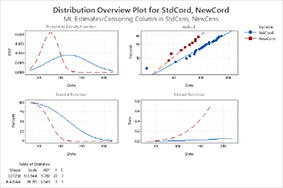

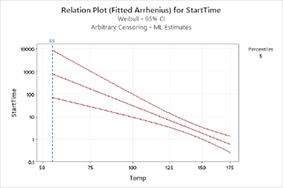

In this course, you will study and describe the impact that explanatory variables have on product lifetime. Learn how to determine the effect of factors and covariates on product failure and the risk of failure to a population of products. Discover how to obtain reliability estimates on highly reliable products in a reasonable amount of time and assess when those components are expected to fail.

You will walk away knowing how to establish appropriate sample sizes and allocate the appropriate amount of units to stress levels for an accelerated life test, then determine the effect of a stress variable on the probability of failure. A strong emphasis is placed on using appropriate probability models to predict important lifetime characteristics of your products, both in test studies and in the field.

Participants of the course will be able to:

Prerequisites: Minitab Essentials, Introduction to Reliability

In this 2-day foundational course, you will learn to minimize the time required for data analysis with Minitab. We will cover how to import data into Minitab, develop sound statistical approaches to explore data, create and interpret compelling graphs, and export results. You will analyze a variety of real-world data sets to learn how to align your applications with the right statistical tool and interpret statistical output to reveal problems with a process or evidence of an improvement. Learn the fundamentals of important statistical concepts, such as hypothesis testing and confidence intervals, and how to uncover and describe relationships between variables with statistical modeling tools.

This course places a strong emphasis on making sound decisions based upon the practical application of statistical techniques commonly used in business, transactional, and services processes.

Topics Include:

Prerequisites: None

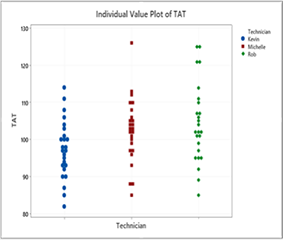

In this course, you will learn the fundamentals of statistical process control and how these important quality tools can provide evidence to improve and control your processes. Develop the necessary skills to successfully evaluate and certify your measurement systems. Plus, practice skills to know when and where to use the various types of control charts available in Minitab. You will understand how to utilize important capability analysis tools so you can evaluate your processes relative to internal and customer specifications.

This course emphasizes the teaching of quality tools as they pertain to service industries.

Topics Include:

Prerequisites: Minitab Enssentials for Service Quality

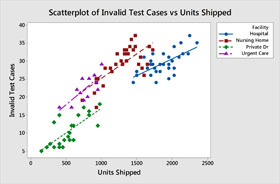

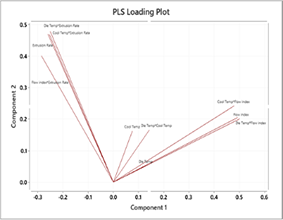

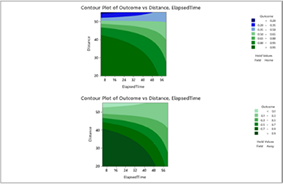

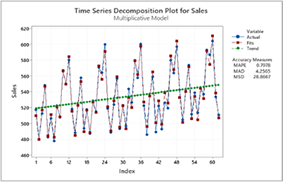

Expand your set of available statistical tools by analyzing data from real-world service industry problems. You will strengthen analysis skills with tools that can be used to explore and describe relationships between variables. Plus, learn to discover and describe features in data related to the effect and impact of time, and how to forecast future process behavior.

Be prepared to utilize graphical and quantitative approaches to describe similarities and differences between the effects of various factors on important quality characteristics. You will learn how to find and quantify the effect that factors have on the probability of a critical event occurring.

Topics Include:

Prerequisites: Minitab Essentials for Service Quality

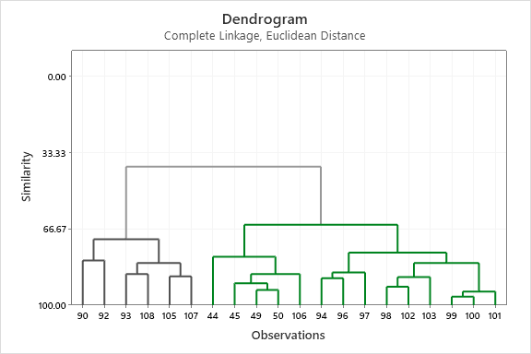

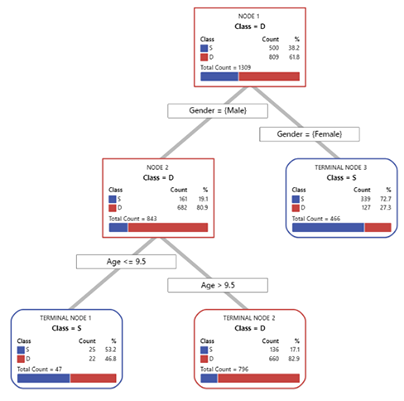

This course will help you expand your data analysis skills with real-world problem examples to teach you how to explore and describe relationships between variables. You will learn to use supervised machine learning techniques, such as CART®, to analyze patterns found in historical data, which can help you gain better insights, identify potential risks, seek out improvement opportunities, and make predictions about the future.

Use unsupervised machine learning tools, such as Clustering, to detect natural partitions in the data and group observations or variables into homogenous sets. Plus, reduce the dimensionality of data by transforming the original data into a set of uncorrelated variables.

Topics Include:

Prerequisites: Fundamentals of Analytics, Regression Modeling and Forecasting

In this 2-day foundational course, you will learn to minimize the time required for data analysis by using Minitab. With Minitab, you will practice importing data, developing sound statistical approaches to explore data, creating and interpreting compelling graphs, and finally, exporting results. By analyzing a variety of real-world data sets, you will learn how to align your applications with the right statistical tool and interpret statistical output to reveal problems with a process or evidence of an improvement. Learn the fundamentals of important statistical concepts, such as hypothesis testing and confidence intervals, and how to uncover and describe relationships between variables with statistical modeling tools.

This course places a strong emphasis on making sound decisions based upon the practical application of statistical techniques commonly used in healthcare.

Topics Include:

Prerequisites: None

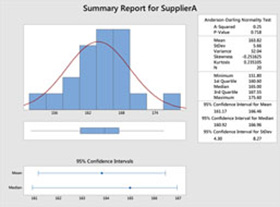

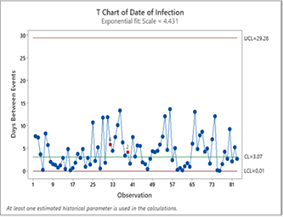

You will develop the skills to successfully evaluate and certify your measurement systems. Learn the basic fundamentals of statistical process control and how these important quality tools can provide the evidence to improve and control your processes. You will practice the skills for knowing when and where to use the various types of control charts available in Minitab. Learn how to utilize important capability analysis tools to evaluate your processes, relative to internal and customer specifications.

The course emphasizes the teaching of quality tools as they pertain to the healthcare industry.

Topics Include:

Prerequisites: Minitab Essentials for Service Quality

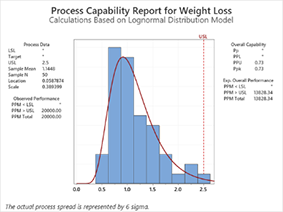

Learn to apply Minitab tools commonly used in the pharmaceutical industry. Develop sound statistical approaches to data analysis by understanding how to select the right tool for a given scenario and to correctly interpret the results of the analysis. Learn how to easily import data and export output.

Learn the foundation for important statistical concepts for determining if a process mean is off target, whether two means are significantly different, and for demonstrating if a process change does not significantly affect a critical response. Develop the necessary skills to successfully evaluate and certify measurement systems. Understand how to utilize important capability analysis tools to evaluate your processes relative to internal and customer specifications. Learn how to evaluate a random sample of product from a lot to determine whether to accept or reject the entire lot.

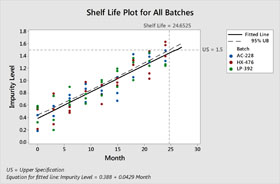

Understand how to apply DOE for process improvement. Learn how to use stability analysis for determining the shelf life of a product. All applications place emphasis on making good business decisions based upon the practical application of statistical techniques commonly used in the pharmaceutical industry.

Topics Include:

Prerequisites: None. This course can be used as a pre-requisite to Response Surface Designs and DOE in Practice.

Learn to apply Minitab tools commonly used in the medical devices industry. Develop sound statistical approaches to data analysis by understanding how to select the right tool for a given scenario and correctly interpret the results. Learn how to easily import data and export output.

Learn the foundation for important statistical concepts for determining if a process mean is off target, whether two means are significantly different, and for demonstrating if a process change does not significantly affect a critical response. Develop the necessary skills to successfully evaluate and certify measurement systems. Understand how to utilize important capability analysis tools to evaluate your product quality relative to internal and customer specifications. Learn how to evaluate a random sample of product from a lot in final inspection to determine whether the lot of product should be shipped. Understand how to apply DOE for improving critical to quality characteristics.

All applications place emphasis on making good business decisions based upon the practical application of statistical techniques commonly used in the medical device industry.

Topics Include:

Prerequisites: None. This course can be used as a pre-requisite to Response Surface Designs and DOE in Practice.