Flexibility

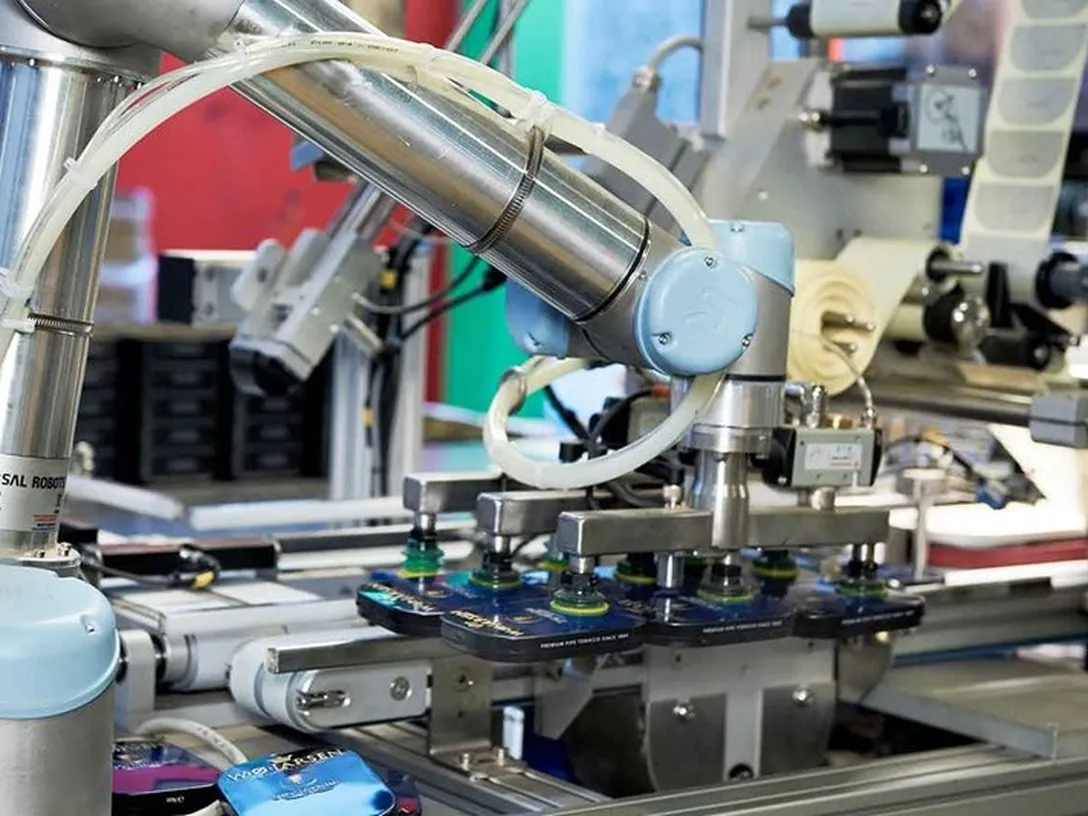

Cobots’ easy programming lets food and beverage producers and packagers quickly adapt to new products and delivery requirements. Collaborative robot arms can be reprogrammed, moved, and redeployed, so even smaller facilities can run multiple lines or switch from production to packaging in the same floor space.

Productivity

Cobots in food and beverage applications can work around the clock to meet even high seasonal demands. Quality isn’t sacrificed for productivity, with accurate, repeatable automation that can reduce waste. A wide range of plug-and-play grippers mean cobots can easily handle delicate and irregularly shaped objects.

Safety & hygiene

Collaborative robots can be implemented to slow down or stop when working side-by-side with human operators in food and beverage processes. While our cobots are not suitable for primary food handling, they are being used widely for handling, packaging and palletizing of packaged foods and beverages.