Material handling

E-commerce and fulfillment growth demands collaborative innovation for automated bin picking and packaging

It’s easy to move our flexible, lightweight robots to the areas where you need application support. When the task is finished, you can re-purpose and re-deploy the robot to other areas in your production.

Improve workplace safety by allowing a robot to handle dangerous tasks. If the robot comes into contact with a person, our patented technology limits the forces at contact. UR robots can also be programmed to operate in reduced mode when a human enters the robot’s work area and resume full speed when the person leaves.

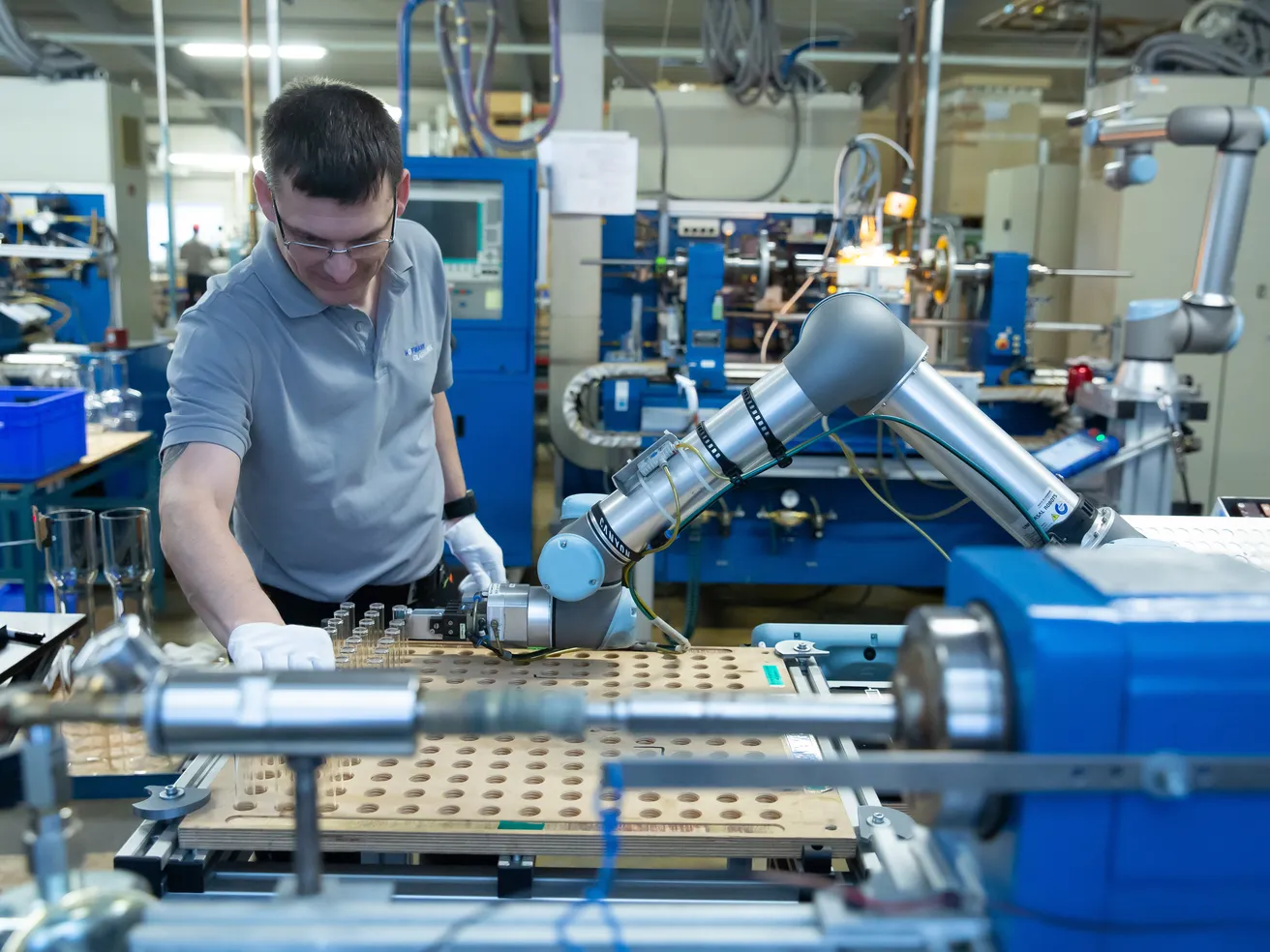

Streamline your material handling, packaging and palletizing, bin picking, labeling and kitting operations with collaborative robots. Relieve workers from repetitive work and heavy lifting by automating material handling tasks with lightweight collaborative robot arms. Automation helps you combat the rising costs of new product packaging and shortened product life cycles, and makes it easy to keep up with seasonal peaks despite labor shortages.

Cobots with innovative grippers, computer vision and machine-learning systems can pick up a wide range of objects even in unstructured environments such as a bins or totes. Easily integrated SKU scanning and the ability to pick up pouches or products of nearly any size or shape make e-commerce, fulfillment, warehousing, logistics and supply chain operations simpler, faster, and more efficient.

The UR robot’s intuitive, easy-to-program interface makes the arm perfect for small-volume applications as well as highly repetitive tasks. You can reprogram and redeploy the robot as needed across your operations. If your workflow changes, the material handling robotic arm can be deployed quickly and easily in new constellations due to its small size and lightweight design.

Our automation experts work with companies like yours to identify applications where cobots can have the biggest impact. They can guide you on training and integration to calculating return on investment.